If you have ever looked up how custom T-shirts are made, you’ve likely encountered the term DTG printing. In fact, you might even know a thing or two about how T-shirt printing works. However, DTG is unique and stands out from other methods in terms of costs and end results. Let’s take a look and see what DTG means, and more importantly, why some companies prefer it over cheaper methods.

The Basics of DTG Printing

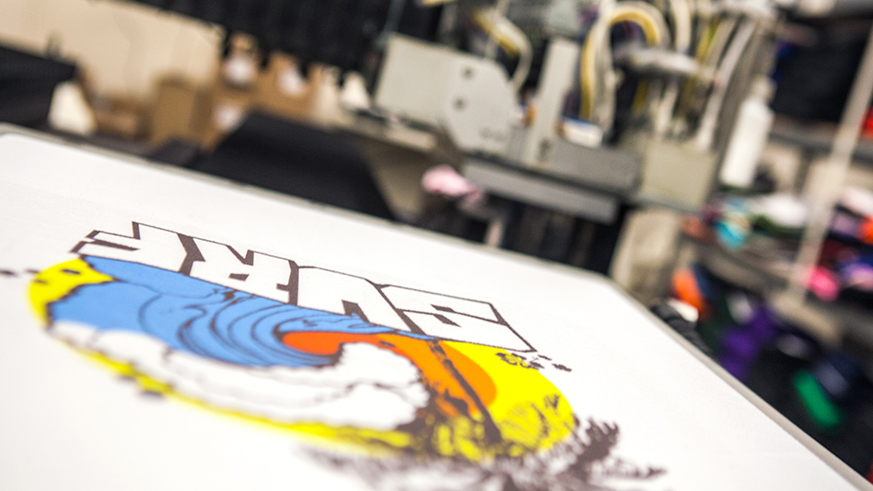

DTG, short for direct-to-garment, is a printing method that sprays ink onto the T-shirt. As a result, the ink soaks into the fabric of the T-shirt, making for a long-lasting and gorgeous design. And while the process sounds simple enough, it requires a special printer filled with special ink. You can think of it as a regular printer, but instead of paper, you use a T-shirt. And rather than printing boring school papers, it prints cool designs.

Unlike similar methods, DTG is a new technology, created in the 90s, becoming commercially available in 2005. Its popularity has grown over the past few years, becoming an alternative to traditional methods. Even so, only a handful of T-shirt printing companies offer DTG as it’s much more costly than other options.

What Types of Designs Work Best With DTG?

DTG printers offer a variety of color options, allowing for extremely detailed designs and images with little to no color limitations. However, DTG is not very fond of transparencies, meaning that elements with a lower opacity than 100% will not translate well in DTG printing. The printer will try to make up for the missing color by spreading the ink, causing gaps in the fabric. That’s why most printing companies use solid colors or simulate semi-transparency by halftoning.

The Advantages of DTG Printing

High-Quality Results

When it comes to quality, there’s no doubt that DTG offers the highest quality print available on the market. Specifically, DTG print is generally produced at 1200×1200 resolution, offering a finer level of details, ensuring that the end design stays crisp. Additionally, allows for an unlimited range of colors, even if some color combinations are more difficult to produce.

Durability

Since the ink is soaked into the fabric itself, the design will most likely age with the garment itself. However, it’s important to note that if the ink has not been applied properly, the design can and most likely will deteriorate and fade.

Comfort and Feel

You might notice that some custom T-shirts are rigid and don’t feel very comfortable. That’s because the print usually reduces the breathability of the fabric, causing the sweat patch effects. Not only that, but depending on the ink, some prints can end up feeling heavy and rough to the skin, making the T-shirt even more uncomfortable.

But luckily, DTG printing has none of those issues, as the printer uses thin, water-based ink. As a result, the fabric stays flexible and you can barely feel it when touching the T-shirt.

Consistency

Most T-shirt printing methods, such as screen printing, have a lot of variables that can influence the end result. Because of that, there is going to be some variation, especially when printing large batches of T-shirts. For example, the last print of the run generally looks a bit different than the first print. On the other hand, DTG is the king of consistency, thanks to a low number of variables involved. As such, it’s the go-to option for large amounts of T-shirt prints with complex designs.

Eco-Friendly

DTG is much more sustainable than most printing methods, mainly because it allows businesses to avoid overproduction and textile waste. Furthermore, DTG printer manufacturers create their products with sustainability in mind, meaning that they produce zero wastewater and use less energy. In fact, some printers use water-based vegan ink, which is toxin-free, biodegradable, and non-hazardous.

The Disadvantages of DTG Printing

Price

When it comes to pricing, DTG is one of the most expensive options out there. That comes as a result of the expensive ink and printer used in the process. Additionally, DTG printers are not maintenance-free machines and often require human supervision when operating. So you can end up spending up to $4 or more to print just a T-shirt, depending on the complexity of the design. The only silver lining is the fact that production costs go down the more T-shirts you are printing.

Time

DTG printers print line by line, just like a regular printer, meaning that the procedure is much slower than similar methods. To put things into perspective, it can take two minutes to print one T-shirt, which is a lifetime when you have thousands of orders. However, T-shirt printing companies overcome that issue via scaling, buying more and more printers to speed up the process.

Pretreating

Before you even start printing your awesome designs, you will have to pretreat the T-shirt, which will add another minute to the procedure length. And while you could pretreat a bunch of T-shirts before, it is not recommended as the pretreatment will degrade, reducing ink adherence. As a result, most shops pretreat each shirt individually just before printing on it.

ArtistShot DTG Printing

If DTG printing seems like the right choice for you, then you should take a look at our product collection. Our goal is to provide you with the highest quality designs available, by using both DTG and Plot Printing. Additionally, we put a huge emphasis on durability, so we make sure that our products are made to last.

So what are you waiting for? Head to ArtistShot and check out the thousands of designs brought to life by our professional designers.

Conclusion

All in all, DTG printing is one of the best printing methods out there, in terms of both quality and durability. However, depending on the number of products printed, the manufacturer might end up losing more money than they earn. Even so, more and more companies are switching to DTG thanks to its eco-friendly and consistent nature. You can expect to see a big rise in the number of websites offering DTG as a new printing option.